Over-Pressured Zones

“Gushers” and Blowouts

Oil and gas exist in underground traps under great pressure in “over-pressured” zones. When the formation containing the oil or gas is penetrated by the drill bit, the oil and gas can potentially blast out of an over-pressured zone with great force.

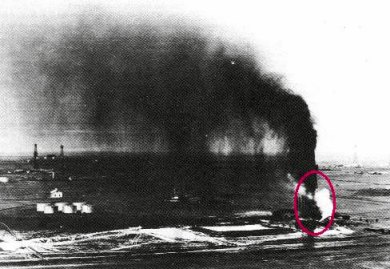

“Wild Mary Sudik” – An Early Gusher — Drilled By The Indian Territory Illuminating Oil Company (ITIO)

In the early days of petroleum drilling, there was no good way to drill holes and simultaneously keep this great force under control. At the left, a well is shown “blowing wild”. This means that the tremendous gas pressure in the reservoir thousands of feet below the ground is forcing huge amounts of oil up the hole, blowing it into the air. This blowout is sometimes called a “gusher.”

The circled well is the Mary Sudik #1, drilled by the Indian Territory Illuminating Oil Company (ITIO) in Oklahoma. On March 26, 1930, this well blew out at 6,470 feet. The force blew 20 pieces of very heavy drill pipe out of the hole! Each piece of drill pipe was 30 feet long.

The “Wild Mary Sudik” was finally plugged off 11 days after blowing out, through the heroic efforts of dozens of people. Six years later, the Sudik lease had produced five million barrels of oil!

Recent “Gushers”

Kuwati Well Fires – Result of War Damage

During the 1991 Gulf War, the retreating Iraqi soldiers dynamited the wellheads off more than six hundred Kuwati oil wells, creating one of the biggest man-made environmental disasters in history. Since most Kuwati wells flow without pumps under their own great pressure, the oil and gas erupted from the ground with tremendous force. It was first estimated that it would take 2 years to repair all the wells. However, the heroic and extremely dangerous job was actually done in about six months.

Deepwater Horizon Blowout

In 2010, the British Petroleum (BP) Deepwater Horizon rig was drilling a well in approximately 5,000 feet (1.5 km) of water in the Gulf of Mexico. When the bit hit a dangerously over-pressured zone, gas escaped up the borehole and ignited at the surface. The rig then collapsed. Subsequently, attempts were made to close the various blowout preventers at the sea floor, but the attempts failed. Finally, the well was shut in approximately 3 months later.

In addition to being one of the most dangerous situations humans can face, as well as an much-unwanted environmental problem, a blowout is considered very bad for the environment, and very bad for business. Most companies make a tremendous effort to avoid spilling a single drop of oil on the ground — or in the water.

Blowout Preventers (BOP’s)

A Blowout Preventer

“Blowouts” have been extremely rare for over 90 years. Blowout preventers (BOP’s) were invented in the 1920’s that allowed the drilling crew to keep the well under control at all times. The BOP came into very wide use in the 1930’s.

There are several types of blowout preventers. They are often combined into one BOP, such as the one at the left. There is an annular BOP at the top. Below that are three ram-type BOP’s.

The annular BOP’s can close tightly around the drilling pipe when they are triggered, sealing off high pressure escaping up the casing from below.

The ram-type BOP’s use a different principle, using horizontal pressure to close around the drill pipe, and some types of ram BOP’s actually cut the drill string in two, completely sealing off the well.

The blowout preventer is mounted below the drilling derrick, right at the surface of the land. On an offshore well, the BOP is mounted at the sea floor.